How Much Will You Make With a Master's in Financial Engineering?

Do you see a math puzzle when you look at [...]

The average salary for industrial engineers varies based on specialization, job title, and level of education. Those with a master's degree earn healthy wages in many fields, including healthcare, aerospace, and electrical engineering. Whatever your interests, a degree program in industrial engineering could be right for you.

Henry Ford’s invention of the assembly line was a significant milestone in American industrial history. This standardized approach to manufacturing resulted in higher efficiency and lower production costs, which allowed for a less expensive, more consistent product. The innovation resulted in better wages for automobile workers, leading to an improved U.S. economy and a stronger middle class.

But the assembly line was just one innovation in the now thriving industrial engineering field. The U.S. Bureau of Labor Statistics (BLS) estimates demand for industrial engineers to grow by an above-average 10 percent by 2031.

So, how much will you make with a master’s in industrial engineering? This article explores that question by covering the following topics:

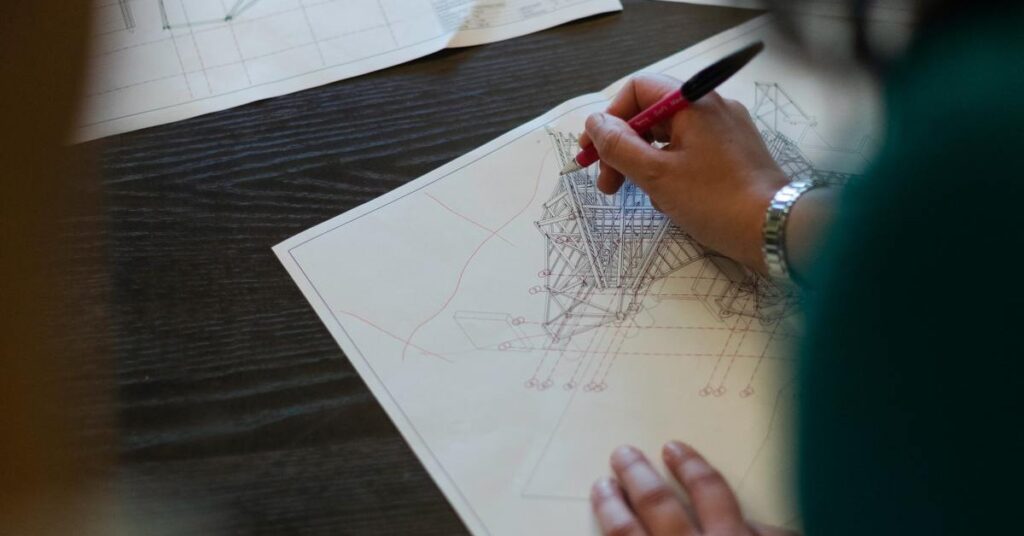

An industrial engineer oversees every aspect of the production phase of project management. They are responsible for designing systems where all the assorted facets (workers, machinery, materials, available budget, data, etc.) work together to maximize efficiency. They may build systems from the ground up or evaluate and redesign existing systems. They can work on the production floor or in offices. The work of industrial engineers varies drastically by employer and sector.

Industrial engineers may be responsible for any of the following:

To qualify for a master’s degree program in industrial engineering, you must have a bachelor’s degree in industrial engineering or a related topic such as mechanical engineering, electrical engineering, systems engineering, or industrial engineering technology.

Typical courses in a graduate program in industrial engineering include:

Specialized courses within industrial engineering include:

Industrial engineering programs generally focus on skills like manufacturing, efficiency, and productivity. In addition, industrial engineers must excel in effective communication, critical thinking, creative thinking, project planning, quality control, and problem-solving.

A Master of Science in Industrial Engineering generally takes two years to complete. However, students can exercise some degree of flexibility to finish earlier through accelerated programs or later if they choose to study only part-time or through self-paced online courses.

Master’s candidates can choose to take their classes through online programs. Case School of Engineering at Case Western Reserve University and the Lyle School of Engineering at Southern Methodist University are two excellent options. Online learning helps students shape their learning plans to fit their scheduling and academic needs.

Industrial engineering is in high demand across many industries. Several specializations can set you apart, including energy engineering, methods engineering, manufacturing engineering, facilities engineering, production engineering, systems engineering, or operations engineering. Those with a mind for finance and computation can even choose to study the subdiscipline of financial engineering.

Below are some jobs you may qualify for once you’ve obtained a degree in industrial engineering. The following salaries represent the national average for these positions. The range will vary depending on the region.

Occupational health and safety managers are responsible for making sure that workplaces adhere to established safety standards so that workers can do their jobs in an atmosphere of relative security. The role requires an understanding of the physical dynamics of the workplace. These professionals write reports detailing the safety history of a given workspace, instruct employees on how to make the workplace safer, and answer safety and health-related questions about the work environment. The median salary for an occupational health and safety manager in the U.S. is $117,730 per year.

Industrial designers fashion and refine models into an optimal product design. They account for available materials, resources, and capital in their calculations. They are also responsible for determining production windows, overseeing inventory, and maintaining quality assurance. The median salary for an industrial designer in the U.S. is $62,486 per year.

Mechanical engineers are concerned with the functionality of machines. They specialize in designing, refining, and testing mechanical and thermal devices to maintain their efficiency. They are also often part of problem-solving teams, representing mechanical solutions. The median salary for a mechanical engineer in the U.S. is $78,715 per year.

One of the benefits of Henry Ford’s assembly line innovation was the assurance of consistency. Quality engineers monitor the conditions of their organization’s products. They are often responsible for setting initial quality standards and working with other production teams in conceiving and implementing tests for both the product and the manufacturing process. In addition, they keep detailed records as the product details evolve. The median salary for a quality engineer in the U.S. is $77,796 per year.

Energy efficiency engineers are responsible for designing and refining energy systems to lower both energy usage and the carbon footprint of commercial, industrial, and residential buildings. The median salary for an energy efficiency engineer in the U.S. is $81,703 per year.

Manufacturing engineers design physical systems to turn a company’s supply of raw materials into usable products. They ensure efficiency, productivity, and safety in the workplace. They regularly evaluate the production process, ensuring machines are in working order. They may also have a say in cost control, quality management, inventory, and the supply chain. The median salary for a manufacturing engineer in the U.S. is $80,120 per year.

Supply chain analysts gather data to analyze an organization’s inventory management dynamics. They find weak points, increase productivity, lower costs, and predict future trends in the supply chain. In addition, they often work with members of other production teams to coordinate best practices across the organization. The median salary for a supply chain analyst in the U.S. is $61,683 per year.

Process engineers determine how raw materials are gathered and formed into usable products. They are adept with best practices across the industry and recognize when a new direction is required to improve manufacturing functions. It’s common for process engineers to work with chemicals, so they often require background experience in chemistry, physics, and mathematics. The median salary for a process engineer in the U.S. is $85,238 per year.

Questions or feedback? Email editor@noodle.com

Do you see a math puzzle when you look at [...]

Operations research mines and interprets data to devise improvements in [...]

The expertise in data analytics you develop through a master's [...]

A Master of Science in Industrial Engineering preps graduate students [...]

Online master's programs are more highly regarded today than ever. [...]

Categorized as: Engineering, Information Technology & Engineering